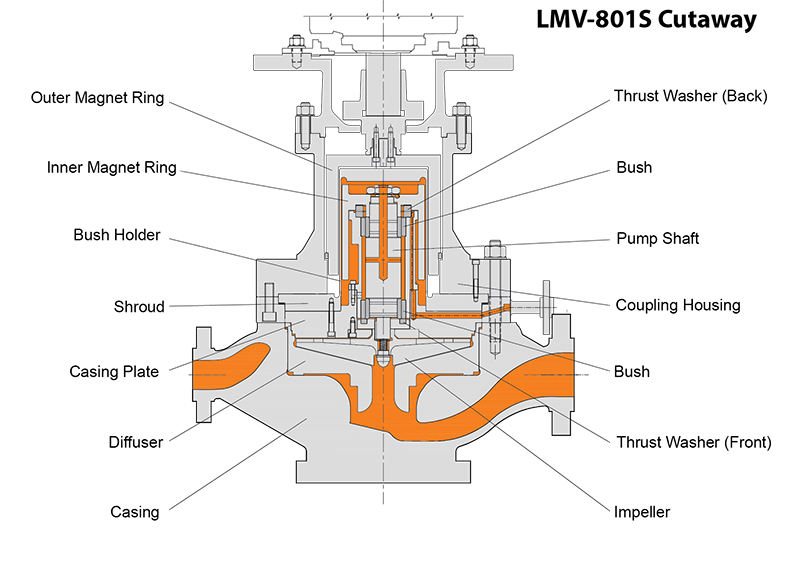

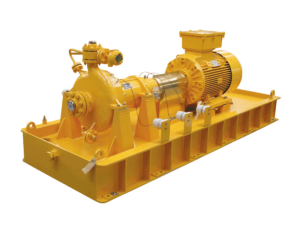

Sundyne Sealless Magnetic Drive API 685 Pump – Safe, Reliable and Economical

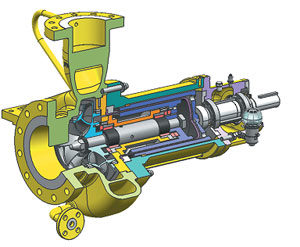

The LMV-801S combines the industry standard hydraulics of the Sundyne direct-drive line of pumps with the magnetic drive technology pioneered by Sundyne HMD Kontro more than 70 years ago. It is built to comply with both API-685 and API-610 standards, and is specifically engineered to eliminate emissions and improve personnel safety without compromising the time-proven production hydraulics of Sundyne direct-drive pumps.

The LMV-801S is dimensionally interchangeable with the traditional mechanically sealed LMV-801 (OH3/5), and can be easily dropped into existing pipework – making this sealless upgrade possible without the need to modify piping and foundation layouts. Additionally, a plug-in version of the pump is available, enabling customers to swap out the mechanical seal drive end with the new sealless option without disconnecting the existing LMV-801 casing and diffuser from the piping.

- Flows to 380 gpm (86 m³/hr)

- Heads to 720 ft (220 m)

- Temperature Range -40 to 400°F (-40 to 205°C)

The vertical configuration of the direct drive line of Sundyne pumps are specifically designed to save valuable space in refineries, NGL production, petrochemical and chemical plants.

APPLICATIONS – PERFECT FOR LIGHT HYDROCARBONS

- Feed pumps

- Booster pumps

- Bottoms pumps

- Wash water pumps

- Reflux pumps

- Condensate pumps

Proven to be reliable, safe, compact and efficient, Sundyne LMV 801S pumps provide a number of operational benefits:

- Single stage, vertical in-line overhung pump according to ISO 13709/API 685 sealless magnetic drive design recommendations

- Sealless magnetic drive can be installed on any existing LMV 801 without changing piping or wet end components

- No leaks for improved safety and environmental contamination

- Safe for handling difficult or hazardous liquids

- Less downtime for maintenance

- Increased durability and reliability with cartridge seals

- Maximized up time

- Saves space-25% the size of competing horizontal pumps

- ATEX certified

- Continuous operations for 5 years with no overhaul

- Barske impeller low NPSH technology

- Reliability of Sundyne hydraulics in a compact sealless magnetic drive design package

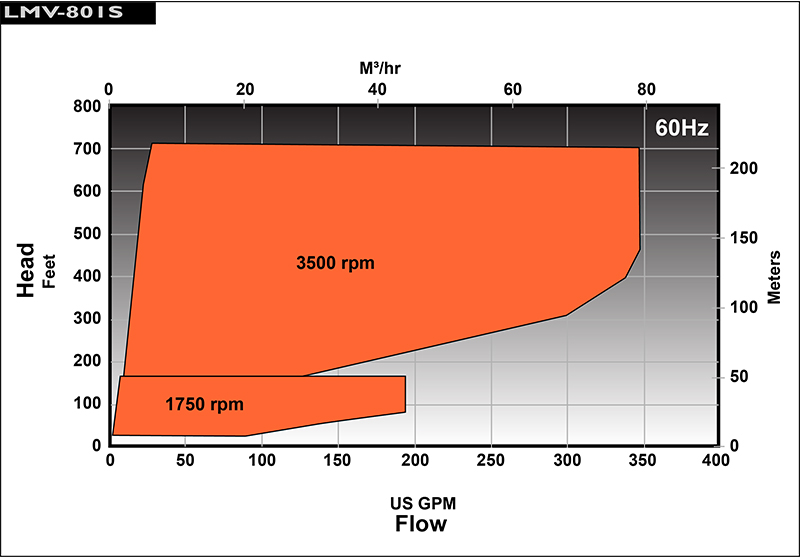

US 60 Hz

- Heads to 720 ft

- Flows to 380 gpm

- Standards API 685

- Maximum Motor Power 100 HP

- Temperature Range -40 to 400°F

- Maximum Allowable Working Pressure 580 psi

- Maximum Suction Pressure 875 psi

- Maximum Viscosity 200 cP

- Solids Range Clean liquids only

- Mounting Configuration Vertical Close Coupled

- Seal Configurations Sealless Magnetic Drive

- Available Inducer Yes

- Available Flanges 600#, 900#, 1500# ANSI RF

- Suction and Discharge Size 3″ x 2″

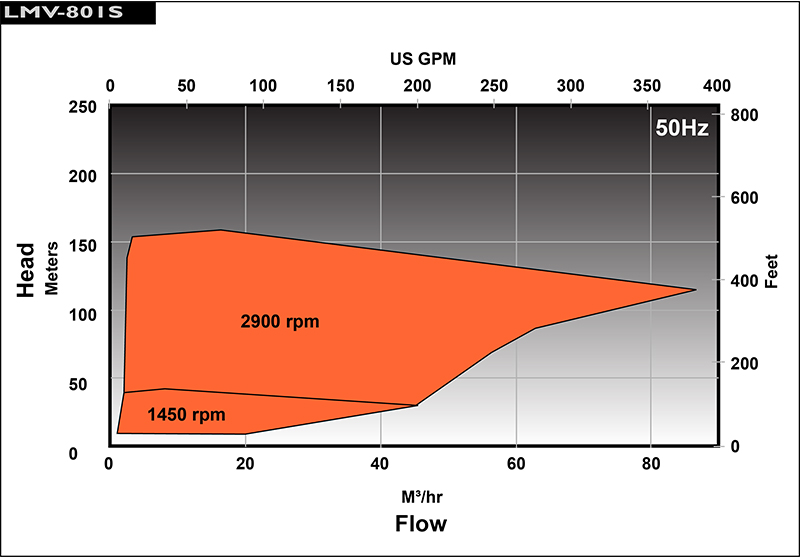

Metric 50 Hz

- Heads to 220 m

- Flows to 86 m3/hr

- Standards API 685

- Maximum Motor Power 55 kW

- Temperature Range -40 to 205°C

- Maximum Allowable Working Pressure 40 bar

- Maximum Suction Pressure 60 bar

- Maximum Viscosity 200 cP

- Solids Range Clean liquids only

- Mounting Configuration Vertical Close Coupled

- Seal Configurations Sealless Magnetic Drive

- Available Inducer Yes

- Available Flanges 600#, 900#, 1500# ANSI RF

- Suction and Discharge Size 3″ x 2″

|

LMV 801CS BUILD CODES |

A |

E |

J |

O (1) |

W |

|

API 610 BUILD (2) |

S-5 (3) |

A-7 (4) |

S-8 (4) |

N/A |

S-9 (4) |

|

Pump Case |

C.S. |

316 SS |

C.S. |

316 SS |

Monel Clad C.S. |

|

Case Studs |

B-7 |

B-7 |

K-Monel |

||

|

Seal Housing |

C.S. |

316 SS |

Monel |

||

|

Separator |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Diffuser Insert |

C.S. |

316 SS |

Monel |

||

|

Diffuser Cover |

C.S. |

316 SS |

Monel |

||

|

Impeller |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Impeller Bolt |

316 SS |

316 SS |

316 SS |

K-Monel |

|

|

Inducer |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Tab Washer |

316 SS |

316 SS |

316 SS |

316 SS |

Monel |

|

Shaft Sleeve |

316 SS |

316 SS |

316 SS |

17-4 PH |

Monel |

|

Shaft (all) |

4140 Steel to 0° F, 15-5 from 0° F to –240° F. |

||||

|

O-rings |

As Required |

||||

- “O” build temperature range 0 to -240°F (115°C) Pressure capability is reduced due to strain hardened pump case studs. Contact Application Engineering.

- See Sundyne Corporation exceptions/clarifications to API 610, 11th Edition for material requirements of pump parts.

- Impeller is upgraded to 316SS. A seal gland is not required because the seals mount in the seal housing. O-rings are used instead of a case gasket.

- A seal gland is not required because the seals mount in the seal housing. The pump shaft is AISI 4140 because it is not exposed to the fluid. O-rings are used instead of a case gasket.

- Diffuser Inserts and Diffuser Covers apply to model LMV-801 only.

POWER MONITOR

Installed in the Motor Control Center (MCC), a power monitor measures the power required to operate the pump. By setting High and Low trip points, the power monitor is the perfect solution for protecting your pump from:

- Dry running

- Low flow operation

- High flow operation

- Severe cavitation

- Magnet de-coupling

New ZeroLoss™ Containment Shell

Reduces Power Losses in the Pump to Zero

- Excellent energy savings can now be made thanks to the introduction of the ZeroLoss containment shell for larger pumps. The elimination of eddy current losses can result in up to a 20% saving in power consumption, further enhancing the benefits and green credentials of magnetic drive technology from Sundyne HMD Kontro.

- The advantage increases in proportion with the magnetic coupling size and is particularly appropriate for larger pumps, making the magnetic drive option even more attractive because through life costs are reduced further. Lower power consumption not only results in reduced running costs but also potentially provides lower initial capital costs, as smaller motors can be specified.

- In addition, installation costs can be reduced as lower-rated cabling may be required, and there are space-savings from the ability to use a smaller base plate for the pump and motor combination.

LONG COUPLED

Long coupled configurations conform to API 685, API 610, ASME/ANSI B73.3 and ISO 2858 dimensions for easy replacement of mechanically sealed pumps (utilizing same baseplate, coupling, guard and motor).

SECONDARY CONTROL & CONTAINMENT

HMD Kontro Sealless magnetic drive pumps are available with secondary control devices to restrict any leaks. Mechanical devices are fitted to the drive shaft assembly and are activated in the unlikely event of containment shell failure. Also, the pump coupling housing is fitted with gaskets to eliminate any leaks across the joining faces.

Solids Handling

All HMD Kontro pumps, as standard, can handle up to 5% hardsolids and 150 microns diameter. The solid size can increase by fitting a self-cleaning in line filter, to 8% solids and 250 microns.

For larger solids HMD Kontro can provide pumps with a clean flush system or filter built into the flush pipework.

Sundyne LMV 801S Sealless Cutaway Pump Poster – PDF

Sundyne LMV 801S Data Sheet US – PDF

Sundyne LMV 801S Data Sheet A4 – PDF

Sundyne Direct Drive API OH3, OH5 Centrifugal Pumps Brochure US – PDF

Sundyne Direct Drive API OH3 and OH5 Centrifugal Pumps Brochure A4 – PDF

Sundyne The Vertical Experts Brochure US – PDF